Cast Iron Stove Makers in Troy in 1872

Troy, New York became a stove manufacturing hub in the 19th century due to its location at the confluence of the Hudson River and Champlain and Erie Canals, and therefore also its easy access to raw materials. A dominant force in the cast-iron stove industry from the 1830s to the 1870s, it was one of the wealthiest cities in the U.S. at the time. The following was published in Scientific American on March 9, 1872.

Troy, New York became a stove manufacturing hub in the 19th century due to its location at the confluence of the Hudson River and Champlain and Erie Canals, and therefore also its easy access to raw materials. A dominant force in the cast-iron stove industry from the 1830s to the 1870s, it was one of the wealthiest cities in the U.S. at the time. The following was published in Scientific American on March 9, 1872.There are in Troy fifteen stove foundries, whose annual consumption of pig iron is about 20,000 tuns, and of coal, 10,000 tuns.

They make 150,000 stoves a year, and give employment to over 1,000 moulders, about 250 mounters and fitters, 300 laborers in different departments of the business, and about 200 skilled pattern makers.

This pattern making is quite an important branch of the stove business, a vast number of patterns being made and shipped to other towns in all parts of the country. The pattern is half the battle in casting stove plates, and has to be as true as possible, and to allow for expansion and contraction in the casting taken from it.

The extent and rapid growth of this trade may be judged from the statement that Troy now manufactures and sells annually 150,000 stoves, and there is, of course, no necessity for fetching any more down from Vermont, whence, thirty years ago, a cargo of stoves arrived in Troy for shipment west over the Erie Canal.

[Vermont and New Hampshire both had robust stove industries, but these were likely made at the furnaces in the Rutland area, or at Burlington.]They came down the Champlain Canal from Vermont, and the young supercargo in charge of them is now a partner in one of the principal stove foundries in the city.

The stove business of Troy, prior to 1845, was limited to four establishments, the oldest of which dates back as far as 1812. A Mr. Arnold was the founder of it. He made his first essay in casting stove plates in 1814, and during that year the molders he employed were deserters from the British Army, which had recently been defeated at Plattsburgh.

[Other early stove makers in the Troy area included William T. James (1815), whose “Baltimore Cookstove” was made and sold in Troy; Troy Air Furnace (1818), built by brothers Alpheus and Truman Hanks and Ephraim Gurley at the southeast corner of Fifth and Grand Division Streets. In 1821, that firm became Starbucks & Gurley, after Charles and Nathaniel Starbuck succeeded the Hanks brothers. Eagle Furnace (1823) was located at 42 Fifth Street; L. Stratton & Son eventually succeeded the original builders, Nazro & Curtis, in 1828. A more proper and complete list can be found here.]Mr. Arnold [who’s identity remains a mystery] conducted a limited business for some years, and then turned his foundry over to Mr. [L.] Stratton, a gentleman who, in after years, became foreman at the West Point foundry, and in 1840, he surrendered his interest in the foundry to James Wager, at present the senior partner in the firm of Wager and Fales, and generally regarded as the oldest stove manufacturer in the United States – not in point of years, but from the time he has been engaged in the business.

From 1840 to 1854, he encountered many trials and pecuniary embarrassments; but he fought his way through them all, enlarged his foundry, quadrupled his business, and he secured a fortune before he left his own foundry in 1855, in spite of the competition created by the erection of half a dozen new foundries between 1846 and 1850.

During those years, he developed marked and valuable improvements in cooking and heating stoves, bestowing great pains on the production of a smoother and better quality of castings. His stoves soon became popular and thousands were shipped to California, and Oregon; a steady sale for them, was found in Australia, and Canada became an extensive buyer in the Troy stove market.

During those years, he developed marked and valuable improvements in cooking and heating stoves, bestowing great pains on the production of a smoother and better quality of castings. His stoves soon became popular and thousands were shipped to California, and Oregon; a steady sale for them, was found in Australia, and Canada became an extensive buyer in the Troy stove market.

Alas, no longer so, the heavy duty on stoves from the States now closes that market to Troy. New England and the South also began to draw a large supply from Troy; while the west began to make itself felt in the Troy market, and the shiploads of emigrants, arriving every week at Castle Garden, pointed significantly to that vast section of the country as a future mine of wealth to the stove foundries.

Of late years Mr. Wager has had a fine business in the manufacture of stoves in association with Mr. Fales, under the style of Wager, Fales & Co.

Philo Stewart

Another great pioneer in the Troy stove business, but as an inventor rather than as a manufacturer, was Philo Penfield Stewart [1798-1868], born in Sherman, Fairfield County, Conn., in 1798. In his boyhood Mr. Stewart exhibited a strong fancy for perfect mechanical workmanship, and was constantly contriving and making miniature machinery.

For this reason, I suppose, his parents compelled him to serve a seven years’ apprenticeship to a saddler an a harness maker, and were astounded to find out, at the expiration of his sentence, that the repository of strap oil did not agree with the lad’s taste.

Of course it didn’t. The boy’s mind was bent on machinery, not on stitching bridles. We next hear of him working as a missionary among the Indians, and at thirty five years of age, as founding the village and college of Oberlin in Ohio.

About this time, poverty compelled him to practice economy, and after some study of cooking stoves he succeeded in constructing one which only consumed three small sticks at a time. It was a stove with a fire box hanging in the oven, and was patented by him in 1838.

Gradually Mr. Stewart turned his entire attention to the invention of new stoves; and when he died in 1868 the names of Stewart’s stoves made a formidable list in the catalogue of stoves manufactured by Fuller, Warren & Co., who hold all his numerous patents.

The dumping grate cooking stove was the result of his greatest efforts, and its capabilities are statistically set forth in the following extract from one of the journals of the day:

The dumping grate cooking stove was the result of his greatest efforts, and its capabilities are statistically set forth in the following extract from one of the journals of the day:

“There were 266 loaves of bread baked, each loaf weighing 1 1/4 pounds, aggregating 332 pounds: or 50 pounds more than the equivalent of a barrel of flour; 72 1/2 pounds of beef perfectly roasted; one bushel of potatoes baked and boiled; 2 barrels of water heated to boiling temperature, all accomplished with 24 1/2 pounds of coal, at 3 1/2 in the afternoon.”

This is cooking by wholesale. If the master saddler and harness maker, to whom Stewart was bound, lived long enough to read the above extract, his ideas concerning the ability of the apprentice whom he thought so stupid must certainly have been considerably modified.

Well, greater men than Mr. Stewart have been pronounced fools by their schoolmasters. Bacon was imprisoned for years on account of his scientific researches. DeCamp and others were confined as lunatics. Mr. Stewart may then be said to have succeeded “excellently well” considering the adverse influences which entrammelled [trampled] his early career.

A man who cannot suit himself with a stove in walking along River Street [in] Troy, must be one of those creatures too often to be met – impossible to please.

He could pick and choose between base burners, self feeders, gas consumers, patent bakers, hot closets, reservoirs, and a hundred, other sorts; and if he happened to be a free handed, liberal minded kind of fellow, he would, in all probability horrify his economical Western wife by taking home one of each pattern.

James Lawson and Fuller, Warren & Co.

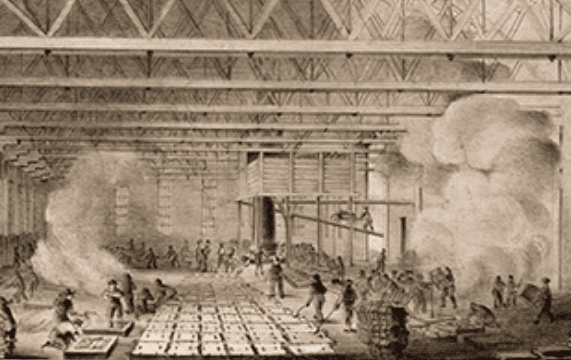

The leading firm in the Troy stove business is that of Fuller, Warren & Co., in which Geo. A. Wells and Walter P. Warren are also active partners. Their foundry is on the Albany and Troy line [the Troy and Greenbush Railroad], immediately adjacent to the celebrated Rensselaer Iron Works, on the outskirts of the city, is known as the Clinton Stove Works, and on a most extensive scale.

It is a large brick structure, covering between five and six acres of ground, and furnishes employment to 400 men. The molding-rooms are the finest I have seen. They are four in number, two being 150 feet square, and the others a little smaller.

It is a large brick structure, covering between five and six acres of ground, and furnishes employment to 400 men. The molding-rooms are the finest I have seen. They are four in number, two being 150 feet square, and the others a little smaller.

Four cupolas, with an aggregate capacity of seventy tuns a day, supply the molten metal for the castings. About forty tuns in the day is the average quantity run. During the busy months of the year, their labor pay roll amounts to $6,000 and $7,000 a week.

Their great stoves are, of course, the different “Stewart” patterns, of which they make about 10,000 a year; but they also manufacture any number of furnaces and ranges. They have special arrangements with Mr. James A. Lawson; which give them the exclusive privilege of making the Lawson furnaces, including the “Diamond” and “Ruby” furnaces.

Mr. Lawson took out his patent in 1864. Since then $800,000 worth of his furnaces have been made and sold by Fuller, Warren & Co.; and this year they fully anticipate making $250,000 worth of them. They are surface burners.

Mr. Lawson, while fully appreciating the merits of base burning as applied to parlor stoves, maintains that the principle is not suitable for furnace heaters; and that a greater amount of heat can be obtained from a surface burner of the same power.

These furnaces weigh from 450 to 2,800 pounds, and find a ready market, like the “Stewart” cooking stoves, from Bangor to San Francisco. Aye! even the delicate toes and fingers of the veiled ladies of the harems of Constantinople are warmed on a chilly afternoon by one of Lawson’s furnaces.

These few figures and facts are all that are needed to point out the thriving condition of the city of Troy, and to call at attention to the talents of her manufacturers whose wares are known in all parts of the world.

Read more about the iron industry in New York State.

Illustrations, from above: Vignette from an advertisement showing the moulding room at Rathbone and Company Stove Works in Albany; Good Baker stove of Troy Stove Works, 1866; A fully equipped Stewart designed stove, 1869; and Clinton Stove Works, home of Fuller, Warren & Co., makers of Stewart stoves, 1869 (illustration by William Barton).

Source link